|

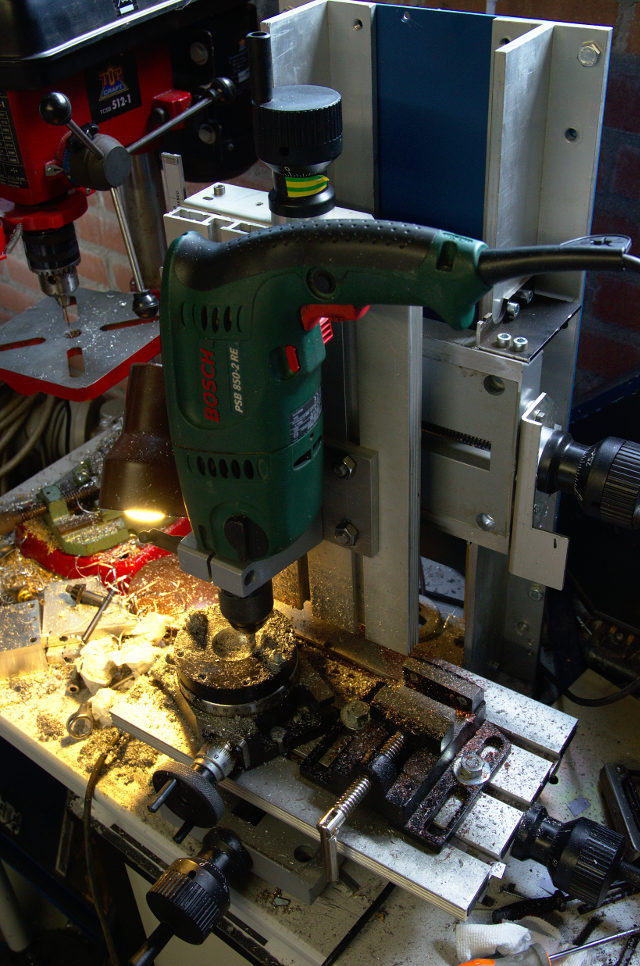

Milling machines are expensive. Even the cheap ones are. As a student even more, that's why I wondered if I could make something myself that would suit my needs, which is machining small laser parts out of aluminum and incidentally copper. Aluminum is an easy material to work with, I figured that for small diameters a homebuild setup would be good enough. The result: a cheap homebuild milling machineThe advantage of 2 stages is that the double axis of freedom provides double the travel range. The normal axis range is just over 100mm, the X direction however is over 200mm. A clamp for the normal work and a rotating chuck for cylindrical coordinated work is mounted next to eachother on the bottom stage. The long travel range makes sure the mill can reach both.After some usage I found out that the Bolts provide too much flexibility, this should be addressed in an upgrade. I also plan to integrate digital calipers to have a measure of the stage position, the stage have significant backlash (~0.4mm mm). The drill will also be replaced by a chuck with proper bearing for milling work. The drill may then still be used to deliver the power, I haven't decided on this yet. |

|