|

I bought a HP 8168D via ebay from Germany. It was advertised as working, but that wasn't the case. So I repaired it. And it was a nice challenge taking such a nice device apart, repairing it and putting it back together. This is my first and still only tunable laser. it goes from 1480nm to 1570nm at ~200uW, peaking somewhere around 1540nm at almost 600uW. Invisible and low power, but it's a tunable laser, and for experiments I don't need high power. The failed selftest on motor 2 |

|

|

Initial inspection

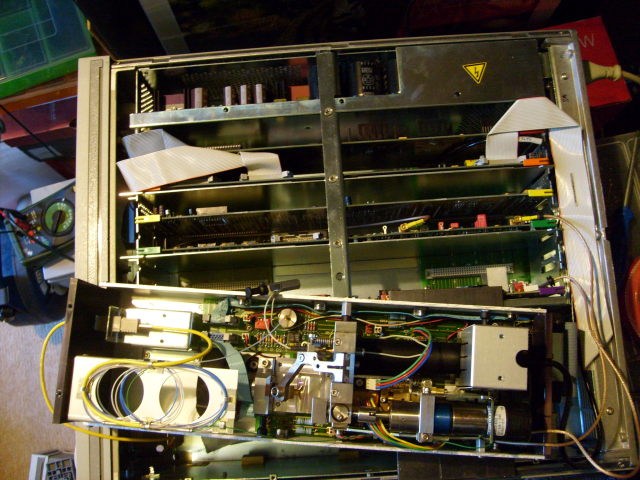

Overview of the laser opened.The laser is quite complicated. From top to bottom: The power supply, nano control (whatever that may be, I'd have to look it up in the manual), microprocessor board 1, microprocessor board 2, etalon control, laser control and finally the optical unit, also opened up. The optical unit is the actual laser, I've taken it out and put it on top of the rest of the laser.

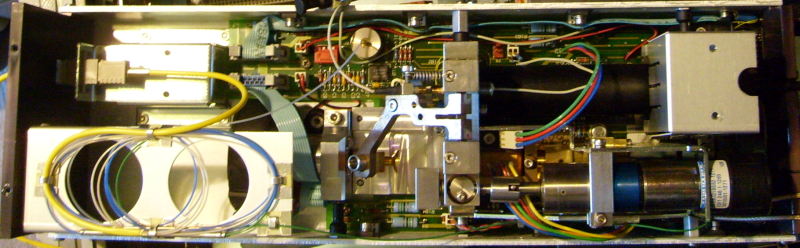

The optical unit taken outThe optical unit has two actuators. In the top right is the black actuator that rotates the grating to tune the wavelength. This motor was making a buzzing sounds. The actuator pushes the arm that hold the grating, but it wasn't moving. In the bottom right is another actuator, this one tilts the grating. It's used to align the cavity sideways. Underneath it is the actual laser diode. It is kept at 55C, pretty hot. This dried the lubrication of the black actuator, causing it to be stuck. On the left of that is the grating on the arm. Between the grating and the laser diode housing is an etalon, controlled by the black motor on the left of it. Completely on the left is the fiber visible. There's a splitter in there and part of it goes back, probably for feedback.

Overview of the optical unitThe cavity of the laser is impressive. One end of the laser diode is coupled into the fiber, the other end is collimated and send out of the diode housing. It reflects back on a grating in littrow configuration. This provide the wavelength specific feedback. The etalon is used to select a single wavelength. Out of the many wavelengths that would still have enough gain to oscillate this etalon picks one out. This guarantees single mode operation.

The actual laser cavity. Ont he left the grating, in the middle the etalon and the hole on the right leads to the laser diode. |

|

|

The problem taken outThe problem was the black actuator that was stuck. I managed to get it out, but I didn't do it the most effective way. Loosenign the whole laser diode housing from the optical unit would make it possible to pull the actuator straight out the back, I partially loosened the whole assembly, but I had to pull it out under an angle with some force. Not advisable with a fragile laser, but hey, it was the first time I did this.

The stuck actuatorNext step is taking the actuator apart. Removing 4 bots got the stepper motor separated from the rod that pushes out. The inbus bolts were filled with some glue, but it can be picked out easily.

The actuator opened upThe pushing rod was stuck, it could be moved but very difficult, too difficult for the stepper motor. I took it out and removed the grease on it with a cloth. After cleaning the rod and the threads inside the casing it already moved much smoother. I got some help from a guy at the university, I asked him for lubrication and he was kind enough to provide some. It was ment for high temperatures and not very viscous. The actuator will now sooner run out of lubrication than get stuck, it moved very smooth.

The pushing rod |

|

|

Putting everything back togetherAfther the lubriation to the stuck actuator was added every thing was put back together inside the optical unit. Before I closed it I check it's operation, and the motor worked again. You can see the grating move and etalon turn as I adjust the wavelength

The optical unitThen I reassembled everything and the laser works perfect ever since

Selftest passed |

|